Presentation

Context

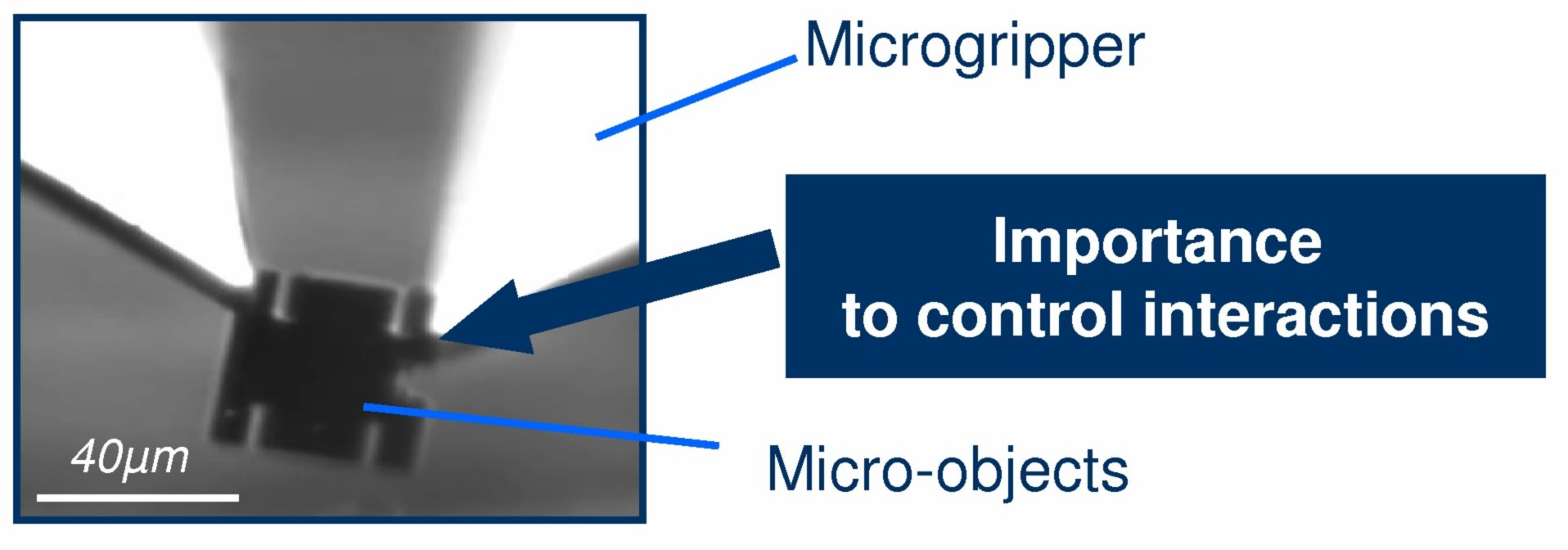

The increase in functionalities of microsystems is usually limited by the fabrication capabilities. In fact, microfabrication technologies are only able to produce 2.5D monobloc structures. The robotic assembly is an interesting and promising way to produce 3D hybrid microsystems with more functionalities. The study of micro-assembly requires to take into account the specific microforces which act in the microscale (microworld). Effectively, surface forces and adhesion forces highly perturb microassembly tasks. This project is focused on robotic micro-assembly where the micromanipulation tasks (pick and place) are specifically complex (see figure). It specifically addresses the modelling, simulation, measurement of non contact and adhesion forces acting at this scale in order to improve micromanipulation and microassembly methods.

Micromanipulation.

The aim of the NANOROL project

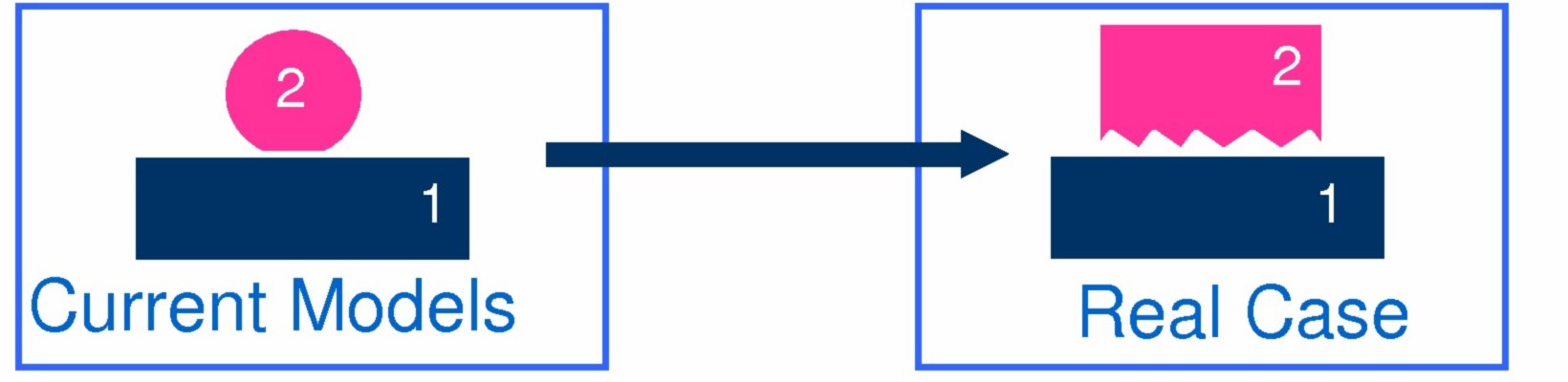

The characterisation (modelling or measurement) of the specific forces of microscale is indeed necessary to design robotic systems for micromanipulation. The study of micromanipulation strategies is usually limited by two major problems:

- the lack of microforce models usable by the robotic community,

- the shortage of force sensors really suitable to measure these effects.

The aim of this project is to develop a scientific platform to adress these issues. The NANOROL platform will be able:

- to simulate the behavior of micro-objects to improve the design of new microrobotic methods,

- to measure the forces to validate the simulations.

Contact between a micro-object and a base.

This platform reaches the objective to be a highly structuring work for french and international microrobotic community as it will improve the knowledge of the microworld phenomena necessary to the development of microrobotic scientific activities.

Final aim

The global objective of this project is the realisation of a scientific platform which is able to analyse the microworld at a nano level the microworld to improve the robotic micromanipulation and usable by international scientists and engineers.